- Home

- About Us

- Machinery

- Paper Cone Production Line

Automatic Paper Cone Plant

-

Automatic Paper Cone Making Machine with Online Drier

-

Automatic Paper Cone Finishing Machine (Twin Index)

Semi Automatic Paper Cone Plant

-

- Paper Tube & Core Production Line

- Composite Can Production Line

- Pulp Moulding Production Line

- Tableware Production Line

- Edge Protector Production Line

- Fibre Drum Production Line

- Square Drum Production Line

- Paper Cone Production Line

- Products

- Projects

- CSR

- Contact Us

A Filtration Leader’s Success Story: Partnering with Sodaltech for Customized Solutions

Innovation knows no bounds, especially when it comes to meeting the unique needs of our customers. At Sodaltech, we pride ourselves on engineering solutions that exceed expectations and drive success. In this case study, we delve into how we customized our Spiral Paper Tube winding machine to cater to the specific requirements of a US-based company in the filtration industry.

The Customer:

Our customer, a leading provider of filtration solutions in the US, serves diverse sectors such as oil and gas, refining, chemical, and petrochemical industries. They manufacture complete systems, vessels and a wide range of cartridges to optimize filtration processes and are pivotal in fulfilling worldwide energy needs demands.

Challenge:

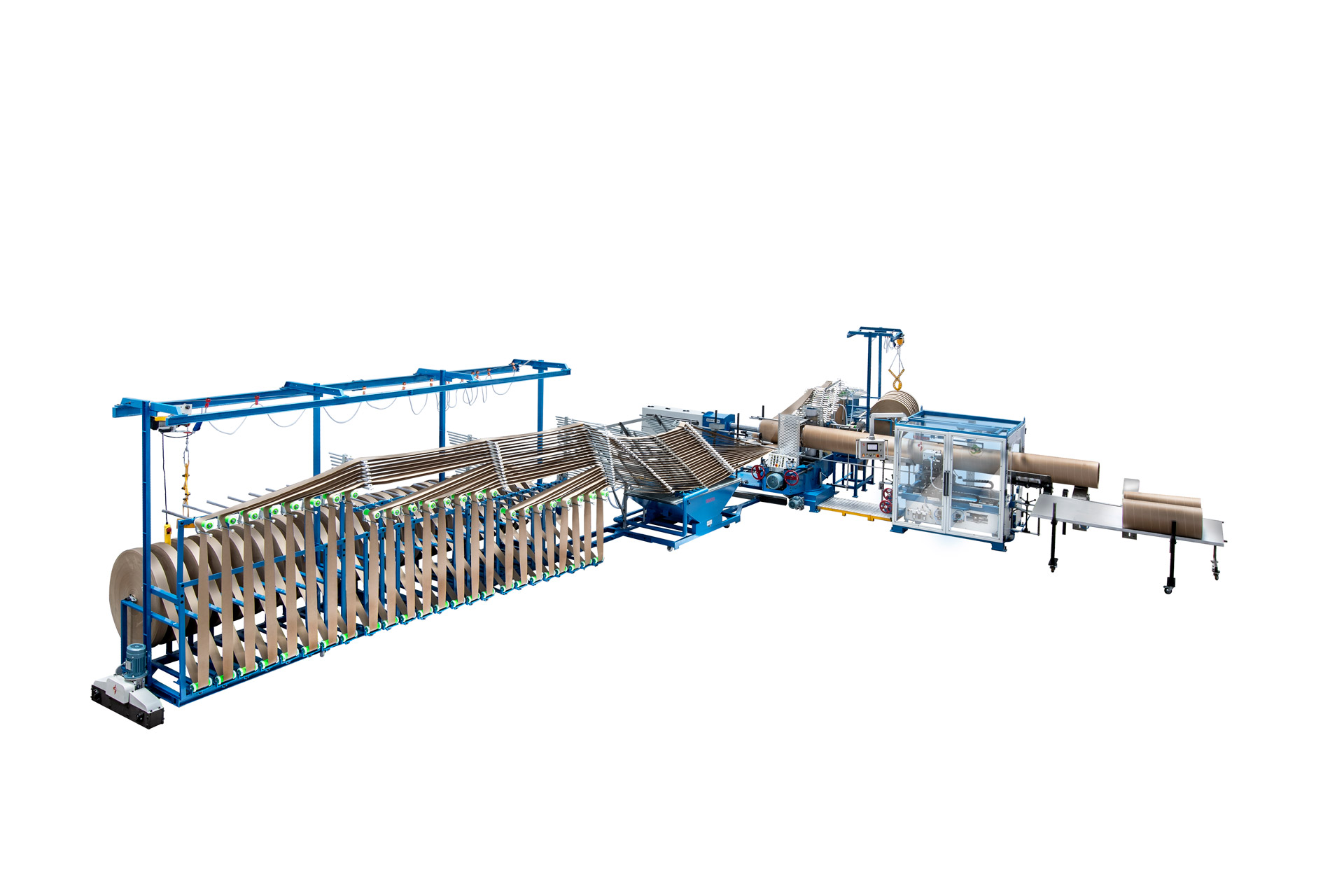

The customer approached us with a complex challenge. They needed tubes made of synthetic fabric with precise specifications that our standard models couldn’t accommodate as they had only single or double winding stations. Specifically, the customer required tubes ranging from 50mm to 108mm in inner diameter, with a maximum wall thickness of 17.5mm and lengths up to 1850mm. Additionally, they needed a spiral tube winder with multiple winding stations synchronized with an online fine-cutting unit, a feature not available in our standard models.

Solution:

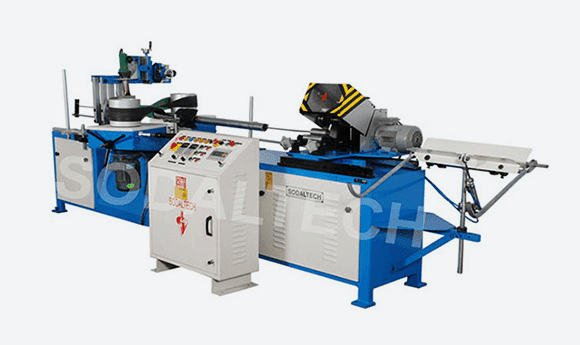

To meet the customer’s exacting requirements, we took on the challenge of customizing our Spiral Paper Tube winding machine. Leveraging our engineering expertise, we designed a specialized machine with four winding stations, each equipped with individual drives and a common master drive. This configuration allowed for precise winding of the synthetic fabric tubes with unparalleled accuracy.

Furthermore, we integrated an online cut-off unit powered by a servo drive system, enabling seamless cutting of tubes of varying lengths without the need for secondary cutting operations. To ensure optimal performance, we enhanced the machine with additional mandrel support, guaranteeing smooth operation even under demanding conditions.

Results and Benefits:

The successful commissioning of the customized machine signaled a pivotal achievement in our partnership with the client. Not only were their expectations met, but they were also exceeded, leading to their satisfaction and trust in our capabilities. Within just 18 months of the initial order, the customer placed a second order—a testament to the effectiveness and reliability of Sodaltech’s tailored solutions.

At Sodaltech, we believe in turning vision into reality, and this case study exemplifies our commitment to delivering innovative and customized solutions that drive success for our customers.

ENQUIRY FORM SODALTECH

Don't hesitate to contact us if you would like to know more about what we can do for you.